Christina Clarke

As a gold- and silversmith, the material knowledge I’ve gained through practice makes metal artifacts as legible as documents: the technical processes used to fabricate them can be read in their forms and textures and the marks over their surfaces. Examining the fabrication of decorative arts gives us access to their materiality and an insight into the lived experiences of artisans—an opportunity to step into the shoes of individuals whose daily actions and experiences are rarely recorded for posterity. Since the symbolic value of elite silver material culture is bound up in artisans’ mastery of the medium, understanding how artisans transformed raw silver into these objects illuminates how they were perceived by those who commissioned, admired, and coveted them in their time. However, precious metal items are frequently recycled, so their fabrication is particularly difficult for us to interpret. This is the case for the silver furnishings produced for France’s King Louis XIV (r. 1643-1715) in the late seventeenth century, which, although renowned in their time, only survive as references in the archive. Nevertheless, an artisan can extract details about fabrication from the archive by drawing on practical experience in the medium. In this essay, I explore the materiality of the Sun King’s infamous silver by making an artisanal reading of one set of documents which are largely overlooked: the probate inventories of the goldsmiths credited with their creation. This practical insight highlights how artisanship incited wonder in those who interacted with these objects and played an essential role in how silver was valued in the long eighteenth century.

Feet, late 17th century. Pen in brown ink and gray wash on paper, 49 x 32 cm. Nationalmuseum,

Stockholm. Photo Cecilia Heisser. Image in the public domain.

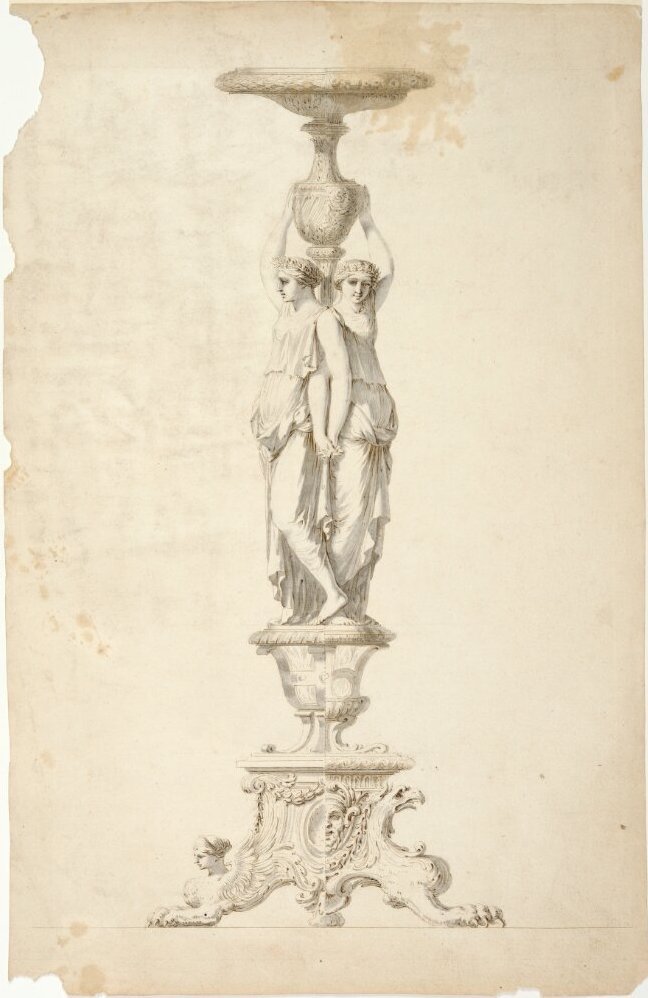

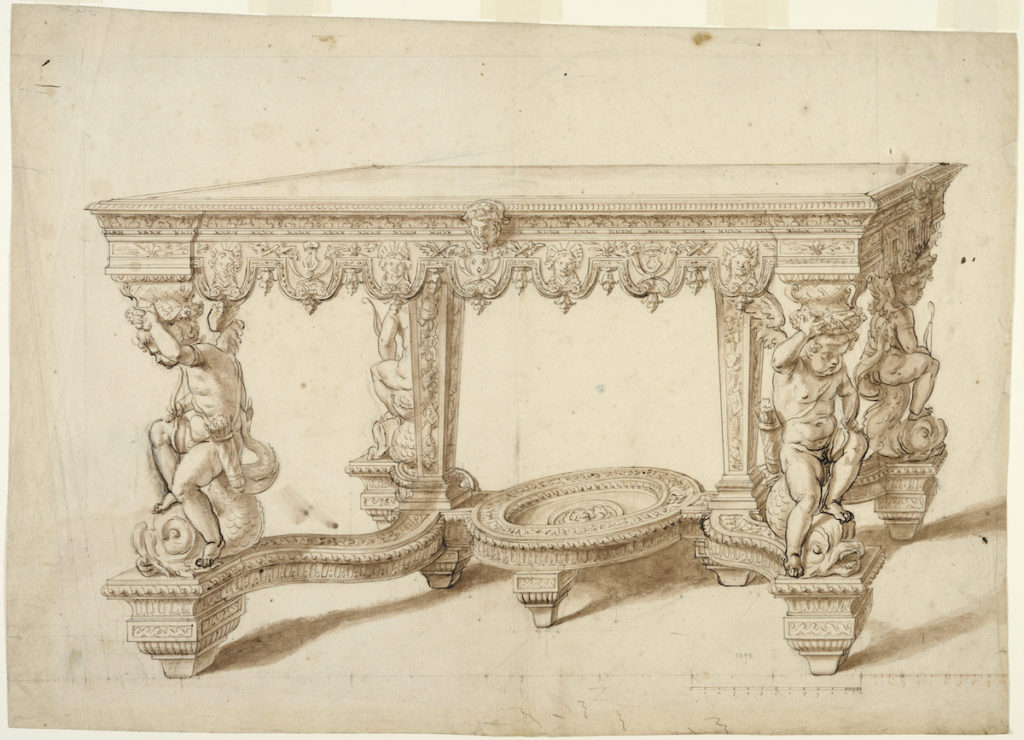

Louis XIV’s silver furnishings are perhaps the most enigmatic silver objects of old regime France. This astounding collection of over one thousand pieces of furniture, lighting, and silverware astonished courtiers and visitors to the royal court, inspiring a fashion for silver furnishings abroad.[1] Most of these, and certainly the largest and heaviest, were produced by royal artisans from the mid-1660s following designs by the king’s chief painter Charles Le Brun. Accordingly, they echoed Le Brun’s unified decorative program celebrating the magnificence and gloire of the Sun King. Examples include 24 ewers—each around 75 cm tall—covered in symbols of Apollo and allegorical figures, with matching basins one meter in diameter; several sets of guéridons—some almost 2 meters tall—formed of two to three figures each (Fig. 1); tables that were 371 kilograms in silver weight with tabletops featuring Apollo on his chariot and allegorical figures of the four corners of the world (Fig. 2).[2] Nevertheless, by order of the king, the entire collection—20 tons of silver—was downcycled to bullion over six months in 1689-90 to pay debts resulting from the War of the League of Augsburg. Other than documentary traces, all that remains of these furnishings are representations in a handful of paintings, tapestries, drawings, and prints.

Most scholarship on these furnishings assumes that they were cast because their recorded silver weights were substantially greater than earlier French and foreign silver furnishings, which were predominantly made from sheet silver affixed to wooden or iron cores.[3] Sheet—produced by hammering metal—is anywhere between 0.5 to 1.5 mm thick, but cast items—produced by pouring molten metal into molds to create the desired form—are heavier because it is impossible to cast metal as thin as hammered sheet. To imagine these furnishings as casts lends an assumption that they had an appearance like bronze sculpture, but in silver. I believe that we must be more specific about technical processes to gain a genuine understanding of the silver furnishings’ material qualities. My artisanal analysis of the furnishings’ weights and measurements indicates that some pieces were predominantly produced from sheet, and it was their enormous proportions that caused their great weights.[4] Objects of this type, such as the ewers and basins described above, were simply oversized versions of traditional silverware. Sculptural pieces such as the guéridons’ figures are more likely to have been cast, but, like the elaborate tables, they must have been constructed from numerous parts—some cast and some fabricated from sheet—all soldered, screwed, and bolted together. Examining the practices of the royal goldsmiths will provide greater insight into Louis XIV’s silver objects.

Crown records attribute the furnishings to 16 goldsmiths, but few of their probate inventories survive.[5] Here I examine those of Claude I Ballin (1615-1678), Pierre Germain (c. 1645-1684), Pierre Merlin (c. 1647-1689), Claude II de Villers (c. 1639-1705), François de Villers (d. 1715), and Nicolas Delaunay (1646-1727).[6] The inventories list their tools, providing a snapshot of each man’s workshop and artisanal practices. These tools should be representative of those that royal goldsmiths used to make the silver furnishings: these men were attributed with a substantial proportion of the collection—Ballin in particular—and Ballin, Germain, and Merlin all died while the silver objects were being produced. The de Villers’ equipment was similar to that of their colleagues who predeceased them, but Delaunay’s inventory lists hundreds of models and no workshop equipment at all.

The equipment these men owned falls into three main categories: tools for heating, silversmithing, and fabrication. Since the fundamentals of the craft have not changed for centuries, I can illustrate the use of some of these tools by demonstrating their use in a contemporary workshop. Regarding terminology, I refer to these artisans as goldsmiths because this was their trade title (orfèvre in French), but they worked in gold, silver, and their alloys, which all have virtually identical working properties. Confusingly, in English, a goldsmith makes jewelry (bijoutier in French), while a silversmith makes tableware, vases, and so on (the craft of silversmithing). Where necessary, I encompass all these variables with the terms “metal” and “metalworking.”

oxygen fuelled torch. Video by the author.

Heat is a critical element in metalworking, and the goldsmiths’ hearth was the only piece of equipment that was substantially different from the contemporary equivalent, gas torches. Like metalworkers for centuries before them, they used wood-fueled brick hearths as a forge and furnace for melting (Fig. 3, background), with accordion bellows providing forced oxygen to raise the temperature as required. As built-in furnishings, forges were not listed in the probate inventories, but their presence is indicated in each workshop by sets of bellows. Very high temperatures (over 900°C) are only required to melt precious metals for casting. Lower temperatures (c. 200-700°C) are used more frequently to solder parts together and to soften metal that has become hardened by hammering—a process called annealing (Fig. 4). Precious metals are typically worked at room temperature, however, so the work is usually cooled after annealing, before work recommences. As one would expect, all the goldsmiths had equipment for handling hot metal, such as tweezers for small items and tongs for large items. They were also equipped with copper boilers for pickling, which is soaking metal items in dilute acid to remove the oxide layer that develops on their surfaces during annealing. Only two goldsmiths had equipment connected to melting: crucibles to contain and pour molten metal, and ingot molds (a, in Fig. 3) for casting blanks to be worked with hammers or other tools. There is no evidence at all that objects were being cast, such as molds or the materials for making molds, but they did have many models, mostly in copper alloys and lead, but also wood, plaster, clay, and wax.

Silversmithing tools outnumbered other equipment in the goldsmiths’ workshops. The term silversmithing, in a narrow sense, refers to the processes for transforming precious metal ingots into objects by hammering (Fig. 3). Typical products of silversmithing are thin-walled hollowware and tableware such as burettes, ewers and dishes, or flatware such as cutlery. Each artisan owned several anvils and a collection of forging hammers for forging sheet and flatware (e in Fig. 3). There were several types of hammers specifically for making hollowware, tableware, and flatware, and shears to cut sheet. They owned eclectic collections of steel stakes for raising sheet metal into hollow forms (Fig. 5). These included horned stakes for making narrow hollow forms such as beakers and the necks of vases (b in Fig. 3 and Fig. 6), domed and ball stakes for rounded forms such as bowls and the bellies of vases (d in Fig. 3 and Fig. 7), and planishing stakes for flattening out dishes (c in Fig. 3). Some stakes had peg fittings to fix them into corresponding holes in wooden stumps (b in Fig. 3 and Fig. 7), while vices bolted to benches or stumps secured other stakes during hammering.

Fabrication tools are used for all the miscellaneous processes necessary for making fittings for hammered pieces, constructing pieces from smaller parts, and ornamenting works. Pliers, hand vices, chisels, and saws served to manipulate wire, rod, and sheet into hinges, lids, handles, candlesticks, pierced work, and pierced appliqué motifs for hammered pieces. Most of these goldsmiths owned draw plates and draw benches for making different gauges and shapes of rod and wire (Fig. 8). Wire could be used to make screws that held parts together, for chain, filigree, and any number of other functional and decorative purposes, while other drawplates were for making decorative moldings for the rims of dishes and similar (Fig. 9). Punches for repoussé and chasing were common to most of the goldsmiths. Repoussé involves hammering punches into pieces made from sheet, such as hollowware, dishes or otherwise flat objects, to create relief ornamentation (Fig. 10). Repoussé deforms the sheet to achieve this but, for chasing, punches are struck lightly to apply thousands of tiny marks over surfaces to create rich textures. Repoussé and chasing are often used in combination.

The inventories indicate that these goldsmiths’ primary technical skills were for producing relatively modest silverware such as vases, tableware, and cutlery. There was nothing at all exceptional about their equipment, so it is all the more impressive that they used these methods to make Louis XIV’s extraordinary silver furnishings. They were certainly equipped to produce oversized silverware like the ewers and basins described above, but the scale would have presented many technical challenges. None of them owned the sophisticated lost-wax and sand-casting equipment that would have been necessary to produce the figures of the guéridons, nor the cast components of furniture like the tables. The presence of models in their workshops indicates that casting played a role in their practices, but it seems that they did not do the casting themselves. Instead, they produced models that they turned over to specialist foundries to mold and cast, and these cast parts were returned to them to be combined with hammered components into the finished furnishings that were delivered to the crown.

We now have more useful insights into the materiality of Louis XIV’s infamous silver furnishings. They were not at all like bronze sculpture. Invariably cast in a single pour, bronzes have an obvious material uniformity that denies attention to small details—the entire surface is continuous and evades technical interpretation. One steps back to observe sculpture and meditate on what it represents, rather than closing in to wonder at technical detail. Conversely, these silver furnishings provoked intimate interactions. Most were visibly constructed from many smaller parts, meticulously fabricated in fine detail. A visitor to the court would have been drawn in to examine this detail and, even if she did not understand the goldsmith’s craft, she would have recognized the evidence of his skill by recalling the more familiar but comparatively modest silverware to which she was accustomed. This contrast with the familiar was doubly emphasized by the oversized silverware, which, although produced in the same fashion as their common elite counterparts, made a mockery of them by their scale. It was not only the value of Louis XIV’s silver furnishings that astonished visitors, nor the abundance, beauty, or Le Brun’s unified iconographic program. Rather, it was all these things set off by the contrast with the familiar accoutrements of elite culture, expressed by the humble skill in the hand of the artisan.

Christina Clarke is Lecturer in Early Modern Art, Design and Material Culture at the Australian National University Centre for Art History and Art Theory

Acknowledgments: This essay stems from a fellowship undertaken in 2018 at the Voltaire Foundation, University of Oxford, which was funded by an Endeavour Research Fellowship from the Australian Department of Education. I am most grateful to Professor Nicholas Cronk and the staff at the Voltaire Foundation for their support. I am also indebted to Robert Wellington for his ongoing feedback on this project, Ruggero Sciuto for guidance in transcribing the inventories referred to here, and the editors of this issue of Journal18, whose suggestions greatly improved this paper.

[1] Michèle Bimbenet-Privat, Les orfèvres et l’orfèvrerie de Paris au XVIIe siècle, 2 vols, (Paris: Commission des travaux historiques de la ville de Paris, 2002), 2:13, 30-32.

[2] Jules Guiffrey, ed., Inventaire général du mobilier de la Couronne sous Louis XIV (1663-1715), 2 vols, (Paris: La Société d’encouragement pour la propagation des livres d’art, 1885), 1:69-74, 77, 86, 91-92.

[3] Carl Hernmarck, The Art of the European Silversmith, 1430-1830, 2 vols, (London: Sotheby Parke Bernet, 1977) 1:215; Bimbenet-Privat, Orfèvres et l’orfèvrerie de Paris, 2:22; Gérard Mabille, “Le Mobilier d’argent de Louis XIV,” in Quand Versailles était meublé d’argent, ed. Catherine Arminjon (Paris: Réunion des musées nationaux, 2007), 65; Florian Knothe, The Manufacture des meubles de la couronne aux Gobelins under Louis XIV (Turnhout: Brepols, 2016), 113-128, n20.

[4] Christina Clarke, “The Sun King’s Silver: An Artisan-Centered Study of the Silver Furnishings of Louis XIV,” West 86th: A Journal of Decorative Arts, Design History, and Material Culture 29, no. 2 (forthcoming 2022).

[5] Jules Guiffrey, ed., Comptes des Bâtiments du Roi Sous Le Règne de Louis XIV, 2 vols, (Paris: Imprimerie Nationale, 1887) 2:37-101; Archives nationales de France, “Journal du Garde-Meuble de la Couronne, 1666-1790,” O1 3304-3323.

[6] Archives nationales de France, probate inventories of: Claude Ballin, 1 February 1678, MC/ET/XCVII/47; Pierre Germain, 5 October 1685, MC/ET/LXIX/454; Pierre Merlin, 14 September 1689, MC/ET/LIX/131; Claude II de Villers, 7 July 1705, MC/ET/XXVI/221; François de Villers, 13 April 1715, MC/ET/XCI/630; Nicolas Delaunay, 22 August 1727, MC/CXVI/256.

Cite this article as: Christina Clarke, “Reanimating the Goldsmith: An Artisanal Reading of the Archive,” Journal18, Issue 14 Silver (Fall 2022), https://www.journal18.org/6502.

Licence: CC BY-NC

Journal18 is published under a Creative Commons CC BY-NC International 4.0 license. Use of any content published in Journal18 must be for non-commercial purposes and appropriate credit must be given to the author of the content. Details for appropriate citation appear above.